|

Zhengzhou yingdi Machinery Co.Ltd

|

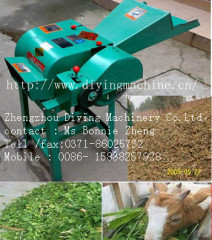

chaff cutter for cow feed crushing machine

| Price: | 4000.0~5000.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Chaff cutter is used for cutting green (dry) of corn stalks, rice straw and other forage crops, straw and

agricultural animal husbandry machinery

Stainless chaff cutter machine

Chaff cutter is used for cutting green (dry) of corn stalks, rice straw and other forage crops, straw and

Chaff cutter is used for cutting green (dry) of corn stalks, rice straw and other forage crops, straw and

agricultural animal husbandry machinery. Fed mainly by the general body, guillotine shear machine,throwing bodies,

transmission, running gear, protection devices and rack components.

Working Principle:

motors or diesel engines are the mating powers. The powers are transmitted to the main shaft. The gears

on the other side of the main shaft transmits the speed- governed power to the grass roller through the gearbox,cardan joint,chains and others. When the the materials under processing

enter into the upper and lower grass rollers and after being fed into the cutting room by the grass rollers and cut in the cutting room,

the materials get out from the outlet hole through high speed cutter.

1.The artifact is simple .the operation is convenient and it is a good helper of household .

2.the machine can combine with electromotor, tractor which is more suitable for the region where lack of electric.

3.The knife is made of high quality rolled steel, durable.

4.The high impact bolt makes it safe to be used.

5.The machine has short, empty, long three gear, can make long and short grass for feed various living the livestock.

6. Low noise, good stability, wet and dry, it is broad raise The budding and ideal produ

Tractor mounted chaff cutter

1: Suitable material : cotton stalk , corn stalk , grass , straw and other agriculture in to small pieces with high capacity ,

2: Power: electricty , diesel engine , tractor PTO Drive

3: Cutting size : 1-5cm

4: Knives : made of 65Mn steel , very durable

Features of this machine

1. Workflow: The workflow of the machine is delivering the stalks to be processed to the kneading chamber by conveyor, kneading the materials through the interaction between hammer leaf revolving in high speed

and kneading plate, and then throwing the kneaded materials out via throwing fan blade.

2. The feeding hopper is equipped with multi-hole spray system so that it can regulate the moisture content and kneading degree of stalks.

3. Structure: feeding hopper, rack, case, rotor and other components.

4. Features: easy operation, great safety and reliability, high production effic

MODEL | OUTPUT(T/H) | MOTO(KW) | Cut size | Machine Size | |

DYZ-1 | 1-1.5 | 3 | 11-54mm | 1000*850*1150mm | |

DYZ-2.5 | 2-2.5 | 4 | 11-54mm | 1230*1150*1695mm | |

DYZ-4 | 2.5-4 | 5.5 | 17-22mm | 1737*1575*2315mm | |

DYZ-6 | 5-6.5 | 7.5 | 12-35mm | 2147*1600*2756mm | |

DYZ-9 | 9-12 | 15 | 12-35mm | 2620*2140*4110mm | |

DYZ-15 | 13-15 | 18.5 | 12-35mm | 2630*2230*4120mm |

iency, etc.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Crushing Machine

Plastic Crushing Machine

Stone Crushing Machine

Feed Machine

Feed Sewing Machine

Cutter Machine

More>>